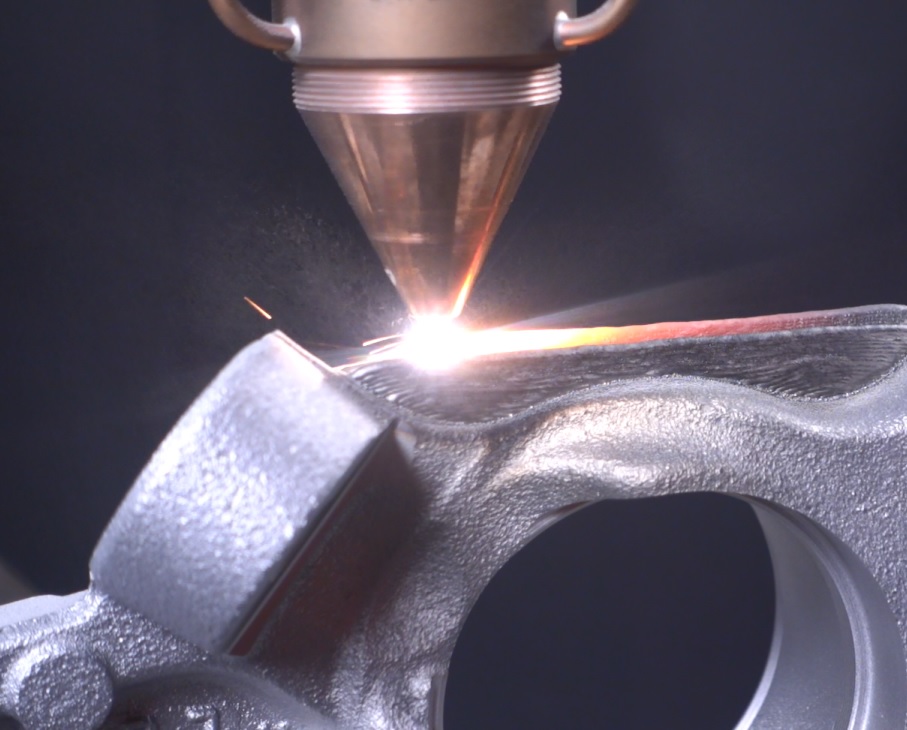

Arc welding processes, such as SMAW, GMAW (MIG), GTAW (TIG), SAW, and others, are widely used in various industries due to their flexibility, high productivity, and relatively low equipment costs. These processes involve the use of an electric arc that melts and fuses the workpiece materials, creating a strong joint.

SMAW (Shielded Metal Arc Welding), also known as stick welding, is commonly used for welding steel and stainless steel in construction, repair, and maintenance applications. The process uses a consumable electrode coated with flux, which produces a protective gas shield to protect the weld from atmospheric contamination.

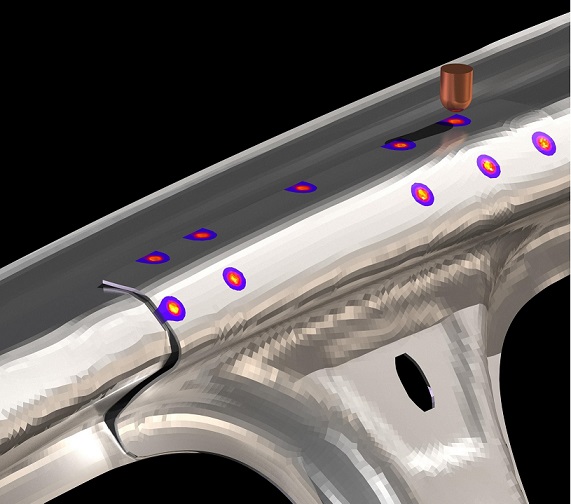

GMAW (Gas Metal Arc Welding), also known as MIG (Metal Inert Gas) welding, is a popular welding process for mild steel, stainless steel, and aluminum. It uses a wire electrode that is continuously fed into the weld pool, along with a shielding gas that protects the weld from atmospheric contamination.

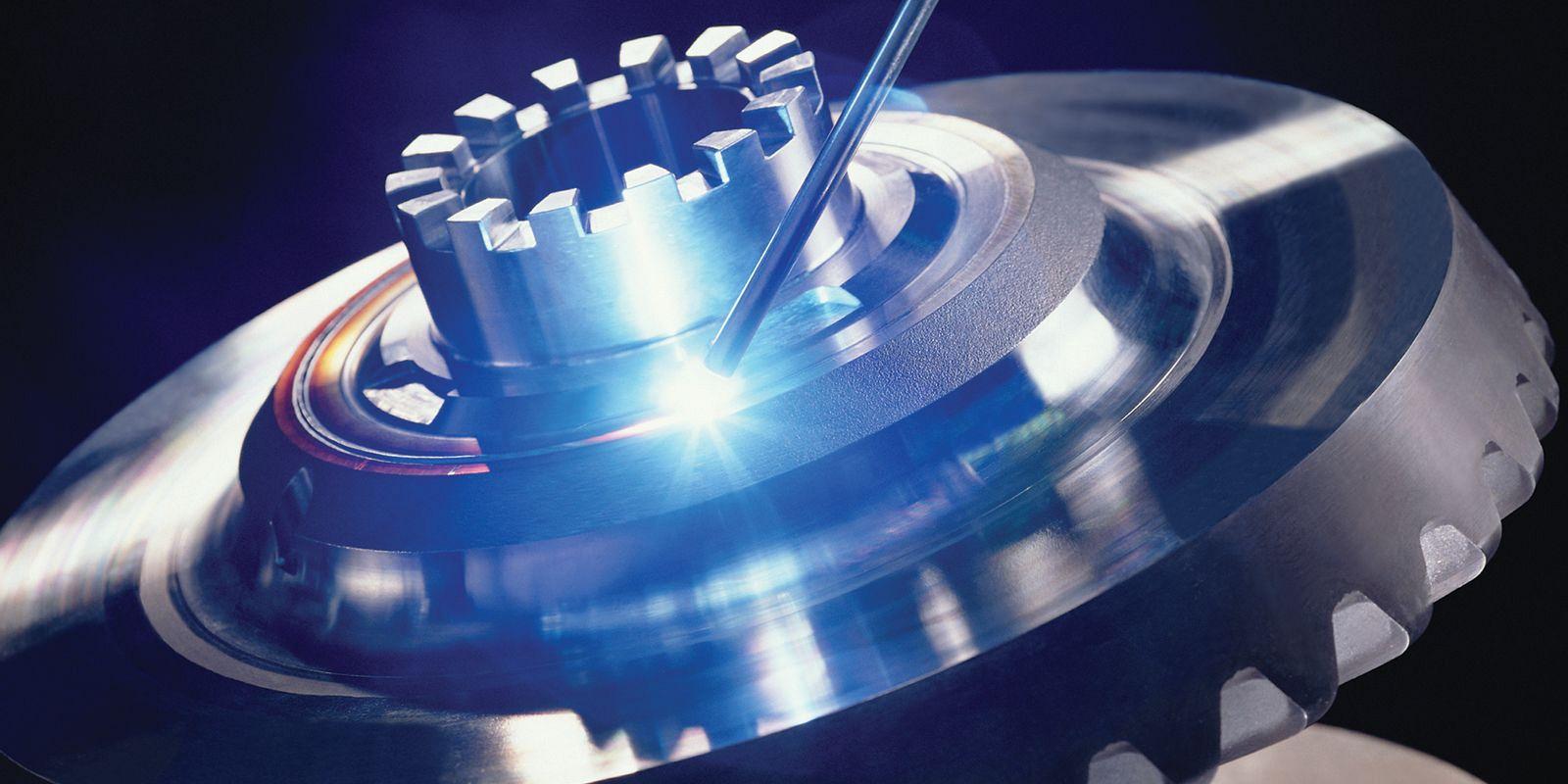

GTAW (Gas Tungsten Arc Welding), also known as TIG (Tungsten Inert Gas) welding, is commonly used for welding thin materials such as aluminum and stainless steel. It uses a non-consumable tungsten electrode and a shielding gas to protect the weld from atmospheric contamination.

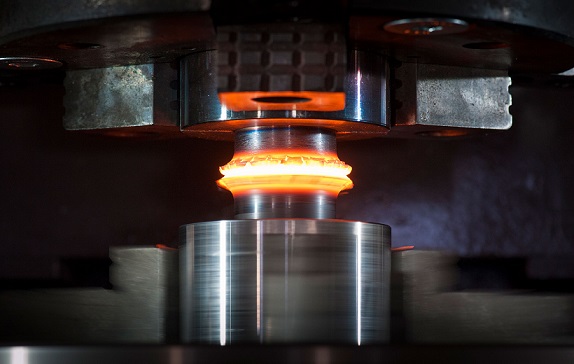

SAW (Submerged Arc Welding) is a high-productivity welding process commonly used in heavy fabrication and manufacturing industries, such as shipbuilding, construction, and pressure vessel manufacturing. The process involves feeding a consumable electrode into a molten pool, which is submerged under a layer of flux that protects the weld from atmospheric contamination.

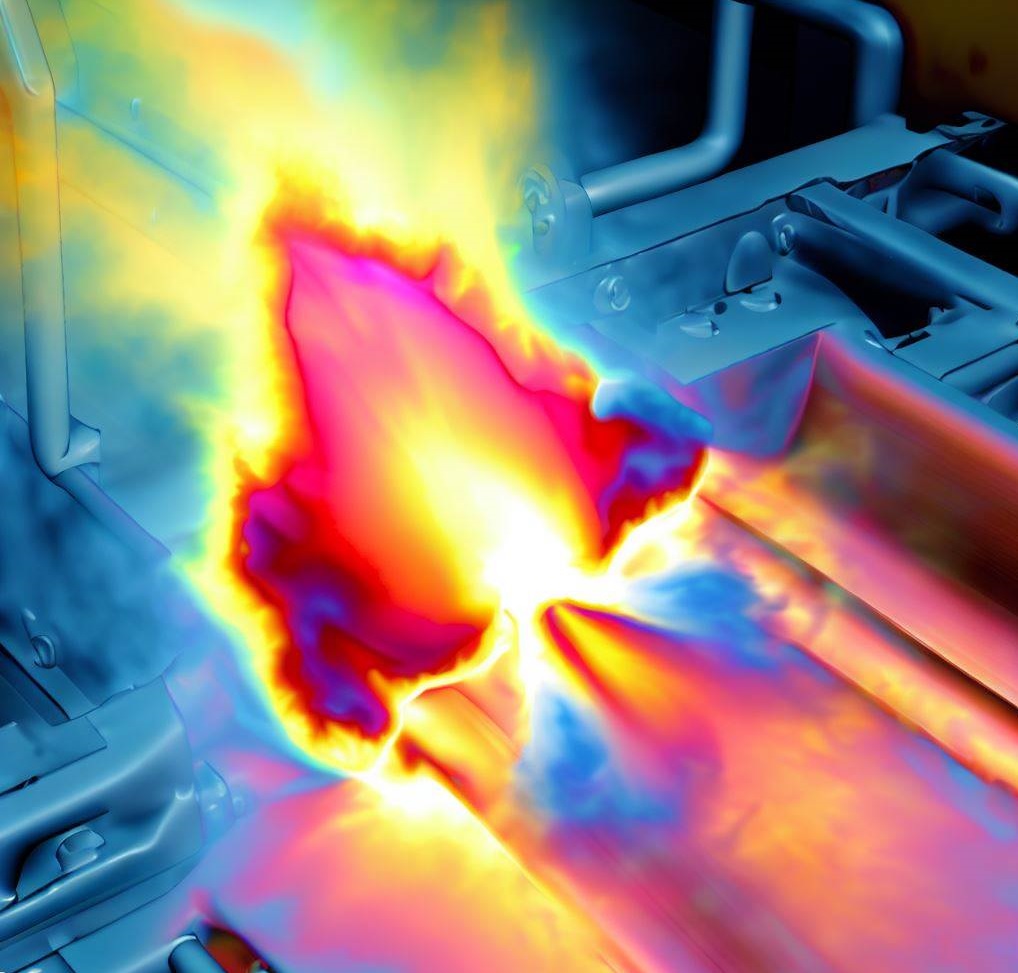

Other arc welding processes, such as plasma arc welding, atomic hydrogen welding, and carbon arc welding, are also used in specialized applications.